Wishlist

SAME DAY DISPATCH FOR UK/EU DESTINATIONS

SAME DAY DISPATCH FOR UK/EU DESTINATIONSSearch

-

AWG Conversion to Millimetre & Inches

How to convert AWG to mm: Wire diameter calculation The n gauge wire diameter dn in millimetres (mm) is equal to 0.127mm times 92 raised to the power of 36 minus gauge number n, divided by 39: dn (mm) = 0.127 mm × 92(36-n)/39 0.127mm is the diameter of gauge #36. Wire cross-sectional area calculation The n gauge wire’s cross-sectional area...

-

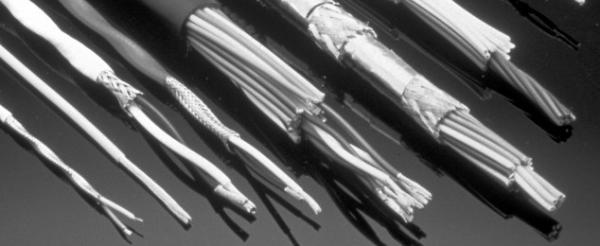

100 Wire Construction

100 Wire, Halogen Free, Low Smoke Conventional cables use filled soft polymer insulations, which by the nature of the insulation have to be a thick wall. 100E wire uses engineered polymers to greatly reduce wall thickness by ~5 times. Characteristics include being extremely flexible, tough and resistant to a variety of fluids meeting the limited fire hazard requirements. Insulation materials are mechanically strong and durable whilst being smaller and... -

99 Wire Construction

Dual Wall 120ºC rated wire, Modified Polyester, Low fire hazard wire and cable Type 99M wire has a dual wall construction of radiation cross-linked modified polyester. This combines excellent mechanical performance and chemical resistance with a range of enhanced fire hazard properties. Type 99M wire is designed to meet the stringent low fire hazard performance being specified by the UK Naval Defence Standard Authority for ship wiring and cabling...

-

55 Wire Construction

Single or Dual Wall 200ºC rated, XL-ETFE, High-performance wire and cable 55 wire is insulated with modified radiation cross-linked ETFE polymer and combines the easy handling of a flexible thin wall wire, with excellent scrape abrasion and cut-through characteristics. The single wall construction is currently used extensively throughout industry, applications include commercial wiring, avionics, satellites, aircraft, helicopters and high-performance military and motorsport electronics or wherever there is a demand... -

44 Wire Construction

Dual Wall 150ºC rated, XL-PVDF, High performance wire and cable SPEC 44 wire has a dual wall construction which combines the outstanding physical and electrical characteristics of radiation crosslinked polyalkene with the excellent mechanical and chemical properties of radiation cross-linked polyvinylidene fluoride (PVDF). The result is a wire insulation system that offers a 150°C temperature rating, small size, light weight, solder iron resistance, and resistance to most solvents...

-

Temperature Rise by Current

The graph (left) illustrates the conductor temperature rise of a single insulated wire in ‘Free Air’. Table A (Below) Conductor size, resistance and current carrying capacity. Table B (Below) Multiplying factor for multicore cables of the same size. Example for 22 AWG twisted pair 7.4 amps (single) x 0.825 = 6.1 amps For further assistance regarding your specific wire and cable... -

Calculating Wire Bundle Sizes

Multiplication Factors for Wire Bundles with Equal Size Wires This table provides multiplication factors for wire bundles of 1 to 61. To determine the approximate diameter of a wire bundle when the wires are all the same size, find the factor for the number of wires in the bundle and multiply the wire diameter by that factor. Calculation of Wire...

-

Shielding Performance

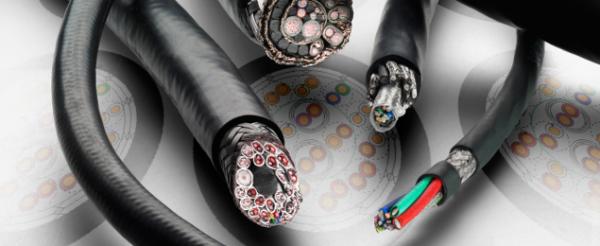

The problems of shielding cables are complex but with the introduction of double and triple optimised braids, we have the solution for the most difficult shielding issues. Shielding of cables without degrading cable flexibility can be provided for coaxial and multiconductor cables. For further information, technical data or assistance with your specific application requirements, please contact us.

-

AWG Conversion to Millimetre & Inches

How to convert AWG to mm: Wire diameter calculation The n gauge wire diameter dn in millimetres (mm) is equal to 0.127mm times 92 raised to the power of 36 minus gauge number n, divided by 39: dn (mm) = 0.127 mm × 92(36-n)/39 0.127mm is the diameter of gauge #36. Wire cross-sectional area calculation The n gauge wire’s cross-sectional area...

-

100 Wire Construction

100 Wire, Halogen Free, Low Smoke Conventional cables use filled soft polymer insulations, which by the nature of the insulation have to be a thick wall. 100E wire uses engineered polymers to greatly reduce wall thickness by ~5 times. Characteristics include being extremely flexible, tough and resistant to a variety of fluids meeting the limited fire hazard requirements. Insulation materials are mechanically strong and durable whilst being smaller and... -

99 Wire Construction

Dual Wall 120ºC rated wire, Modified Polyester, Low fire hazard wire and cable Type 99M wire has a dual wall construction of radiation cross-linked modified polyester. This combines excellent mechanical performance and chemical resistance with a range of enhanced fire hazard properties. Type 99M wire is designed to meet the stringent low fire hazard performance being specified by the UK Naval Defence Standard Authority for ship wiring and cabling...

-

55 Wire Construction

Single or Dual Wall 200ºC rated, XL-ETFE, High-performance wire and cable 55 wire is insulated with modified radiation cross-linked ETFE polymer and combines the easy handling of a flexible thin wall wire, with excellent scrape abrasion and cut-through characteristics. The single wall construction is currently used extensively throughout industry, applications include commercial wiring, avionics, satellites, aircraft, helicopters and high-performance military and motorsport electronics or wherever there is a demand... -

44 Wire Construction

Dual Wall 150ºC rated, XL-PVDF, High performance wire and cable SPEC 44 wire has a dual wall construction which combines the outstanding physical and electrical characteristics of radiation crosslinked polyalkene with the excellent mechanical and chemical properties of radiation cross-linked polyvinylidene fluoride (PVDF). The result is a wire insulation system that offers a 150°C temperature rating, small size, light weight, solder iron resistance, and resistance to most solvents...

-

Temperature Rise by Current

The graph (left) illustrates the conductor temperature rise of a single insulated wire in ‘Free Air’. Table A (Below) Conductor size, resistance and current carrying capacity. Table B (Below) Multiplying factor for multicore cables of the same size. Example for 22 AWG twisted pair 7.4 amps (single) x 0.825 = 6.1 amps For further assistance regarding your specific wire and cable... -

Calculating Wire Bundle Sizes

Multiplication Factors for Wire Bundles with Equal Size Wires This table provides multiplication factors for wire bundles of 1 to 61. To determine the approximate diameter of a wire bundle when the wires are all the same size, find the factor for the number of wires in the bundle and multiply the wire diameter by that factor. Calculation of Wire...

-

Shielding Performance

The problems of shielding cables are complex but with the introduction of double and triple optimised braids, we have the solution for the most difficult shielding issues. Shielding of cables without degrading cable flexibility can be provided for coaxial and multiconductor cables. For further information, technical data or assistance with your specific application requirements, please contact us.