SAME DAY DISPATCH FOR UK/EU DESTINATIONS

SAME DAY DISPATCH FOR UK/EU DESTINATIONSHigh-performance heat shrink tubing products provide an easy and cost-effective solution in a range of applications in demanding environments, providing protection to electrical wiring, splices and fluid management in a wide range of vehicle types, from industrial to defence vehicles as well as motorsport.

Adhesive lined tubing products can reliably seal and protect against moisture and fluid, corrosion, and extreme temperatures.

Available in a wide range of materials that offer different degrees of flexibility, we supply heat shrink tubing that can meet a range of automotive industry standards in flame retardant and halogen-free options that are RoHS/ELV compliant.

Chemical & Abrasion Protection

| Application | Challenge | Products |

Engine bay cable protection |

Protection of electrical cables and components

High temperatures Fluid Resistance Abrasion Protection Flexibility |

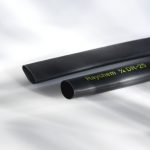

DR-25

Excellent fluid resistance -75°C to +150°C |

Hoses |

Compact spaces

Cooling hose proximity to engine components Abrasion/ChafingFlexibility |

HFT5000 Flexible fabric, easy installation Excellent abrasion protection Meets automotive abrasion specs Safe installation without hot knife cutting equipment -40°C to +125°C 2:1 Shrink Ratio at +110°C Fluid resistant |

Brake Pipes |

Exposure

Damage and corrosion |

AP-2000 Protection from corrosion Flexible for bending after installation Adhesive seal prevents moisture ingress -40°C to +80°C Shrink Temp: +110°C Fluid resistant |

Air Conditioning |

Insulation & Protection

Corrosion Thermal Insulation |

RPT-120

Easy installation -40°C to +120°C AP-2000 -40°C to +80°C

|

Diesel Injection Clusters |

Noise reduction | ATUM Noise dampening Moisture-proof adhesive seal -55°C to +110°C |

Strain Relief

| Application | Challenge | Products |

Connectors |

Rigid cabling Tight radius bends Moist and high temperature engine bays |

CRN

Excellent abrasion resistance -55°C to +135°C HTAT -55°C to +125°C

|

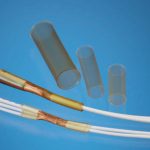

In-line Splices |

Protection

Splice insulation Reinforce crimp connection |

RPPM

Low profile -40°C to +85°C

QSZH Adhesive lined for strong bond -40°C to +125°C |

Miniature Splices |

Protection

Fragile wire splices |

Sealing

| Application | Challenge | Products |

In-line Splices |

Moisture Protection Water & salt spray corrosionWeak splice joints |

QSZH

Adhesive lined for excellent sealing -40°C to +125°C Low profile -40°C to +85°C Excellent sealing -40°C to +150°C |

End Splices |

Sealing | ES-CAP

Strain relief and abrasion protection -40°C to +125°C |

Connector |

Protection

Two to 18 way connectors require sealing from wet and high temperatures in the engine bay. |

HTAT Low profile, semi-flexible Strain relief and sealing, moisture proof High strength bond -55°C to +125°C

SCT -40°C to +150°C |

Ring Terminals |

Protection

Corrosion from moisture Mechanical damage and strain |

QSZH

Adhesive lined for excellent sealing -40°C to +125°C

Excellent sealing -40°C to +150°C

Protection against flexing, abrasion and cut-through -55°C to +125°C |

Wire Bundles |

Protection

Moisture/water Larger wire bundles |

RayBlock Sealing Kit

Low profile sealing RayBlock 85 -40°C to +85°C RayBlock 105 -40°C to +105°C |

Identification & Aesthetics

Fuel pipes |

Environment

Reduce use of solvents and chemicals by replacing paint. |

LSTT

Rapid, low-temperature recovery -40°C to +125°C CGPT Chemical/solvent resistant -40°C to +135°C |

Ring Terminals |

Identification

Identify voltage, ground and signal wires. Prevention of incorrect connections for the life of the vehicle. |

RBK-RTP

Protection against flexing, abrasion and cut-through -55°C to +125°C Chemical/solvent resistant -40°C to +135°C

|

Cosmetic

Seat Belt Stalks |

Appearance

Functional yet pleasing finishing. |

TUGA

Uniform conformity and less length change -55°C to +125°C Rapid, low-temperature recovery -40°C to +125°C |

Gas Springs |

Appearance and Protection

Corrosion and damage Alternative to paint |

RPT-120

Tough layer with good finish -40°C to +120°C |

Antenna |

Protection

Glass or fibre wound antennas need protective covering. |

CGPT

Chemical/solvent resistant -40°C to +135°C

RPPM-NR801 Mechanical strength and flexibility -40°C to +85°C |